Basic Magnet Design

Lub tshuab Magnabend yog tsim los ua ib lub zog DC hlau nplaum uas muaj lub luag haujlwm tsawg.

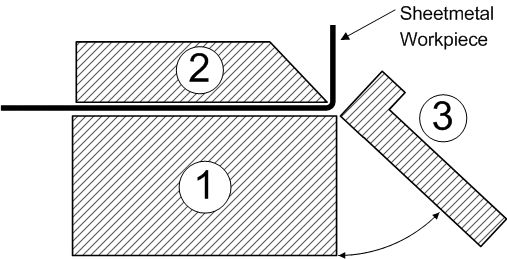

Lub tshuab muaj 3 qhov tseem ceeb: -

Lub cev hlau nplaum uas tsim lub hauv paus ntawm lub tshuab thiab muaj cov electro-magnet coil.

Lub clamp bar uas muab txoj hauv kev rau cov hlau nplaum sib nqus ntawm cov ncej ntawm lub hauv paus hlau nplaum, thiab yog li clamps cov ntawv hlau ua haujlwm.

Lub beam dabtsi yog khoov uas yog pivoted rau pem hauv ntej ntug ntawm lub hlau nplaum lub cev thiab muab ib tug txhais tau tias rau siv dabtsi yog khoov quab yuam rau lub workpiece.

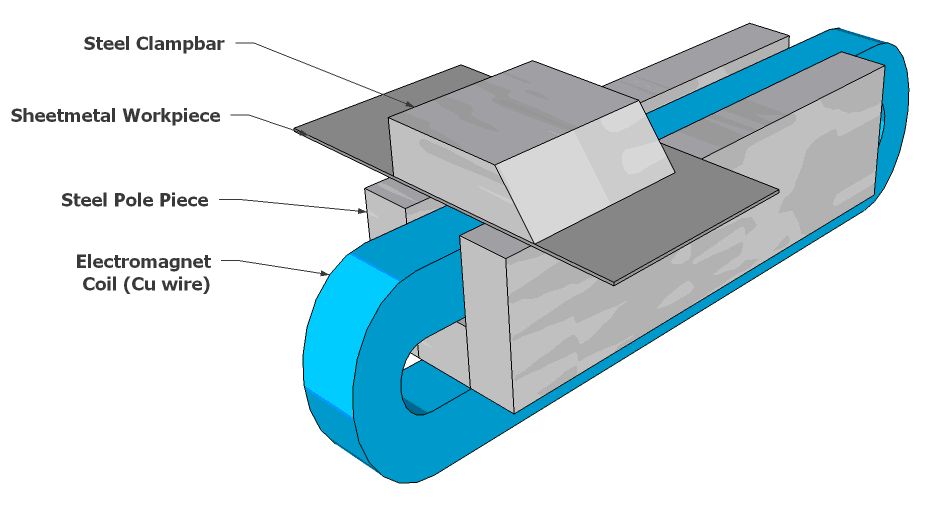

Qauv: 3D

Hauv qab no yog ib daim duab 3-D uas qhia txog qhov kev npaj ntawm qhov chaw hauv U-hom hlau nplaum:

Lub luag hauj lwm Cycle

Lub tswv yim ntawm lub voj voog lub luag haujlwm yog ib qho tseem ceeb heev ntawm kev tsim cov tshuab electromagnet.Yog tias tus qauv tsim muab ntau lub luag haujlwm lub voj voog ntau dua li qhov xav tau ces nws tsis zoo.Ntau lub voj voog ua haujlwm hauv lub cev txhais tau hais tias yuav xav tau ntau cov tooj liab hlau (nrog rau tus nqi siab dua) thiab / lossis yuav muaj tsawg dua clamping quab yuam.

Lus Cim: Lub voj voog ua haujlwm siab dua yuav muaj lub zog qis dua uas txhais tau tias nws yuav siv lub zog tsawg dua thiab yog li pheej yig dua los ua haujlwm.Txawm li cas los xij, vim tias cov hlau nplaum yog ON rau lub sijhawm luv luv xwb ces tus nqi zog ntawm kev ua haujlwm feem ntau suav tias yog qhov tseem ceeb tsawg.Yog li txoj kev tsim qauv yog kom muaj lub zog ntau npaum li qhov koj tuaj yeem tau txais mus rau hauv cov nqe lus ntawm tsis overheating lub windings ntawm lub kauj.(Qhov kev qhia no feem ntau yog cov qauv tsim hluav taws xob electromagnet).

Lub Magnabend yog tsim los rau lub voj voog nominal ntawm kwv yees li 25%.

Feem ntau nws tsuas siv 2 lossis 3 vib nas this los ua qhov khoov.Cov hlau nplaum yuav tawm mus ntxiv rau 8 mus rau 10 vib nas this thaum lub workpiece repositioned thiab ua raws li npaj rau qhov khoov tom ntej.Yog tias 25% lub voj voog ua haujlwm dhau lawm ces thaum kawg cov hlau nplaum yuav kub dhau thiab thermal overload yuav mus.Cov hlau nplaum yuav tsis puas tab sis nws yuav tsum tau tso cai kom txias li 30 feeb ua ntej siv dua.

Kev ua haujlwm nrog cov tshuab hauv thaj chaw tau pom tias 25% lub luag haujlwm lub voj voog yog qhov tsim nyog rau cov neeg siv khoom.Qhov tseeb qee cov neeg siv tau thov kev xaiv lub zog siab ntawm lub tshuab uas muaj ntau lub zog clamping ntawm tus nqi qis dua lub voj voog.

Magnabend Clamping Force:

Tswv yim Clamping Force:

Nyob rau hauv kev xyaum no siab clamping quab yuam tsuas yog puas tau pom thaum nws tsis xav tau (!), uas yog thaum khoov nyias steel workpieces.Thaum khoov tsis-ferrous workpieces lub zog yuav tsawg dua li qhia hauv daim duab saum toj no, thiab (me ntsis xav paub), nws tseem tsawg dua thaum khoov tuab steel workpieces.Qhov no yog vim hais tias lub clamping quab yuam uas yuav tsum tau ua kom ib tug ntse khoov yog ntau ntau dua li qhov xav tau rau lub vojvoog khoov.Yog li dab tsi tshwm sim yog tias thaum khoov mus rau pem hauv ntej ntug ntawm lub clampbar nqa me ntsis yog li cia lub workpiece tsim ib lub vojvoog.

Qhov me me-qhov sib txawv uas yog tsim ua rau me ntsis poob ntawm lub zog clamping tab sis lub zog xav tau los tsim lub vojvoog khoov tau poob ntau dua li muaj cov hlau nplaum clamping quab yuam.Yog li qhov teeb meem ruaj khov tshwm sim thiab lub clampbar tsis tso tseg.

Dab tsi tau piav qhia saum toj no yog hom kev khoov thaum lub tshuab nyob ze nws cov thickness txwv.Yog hais tias ib tug txawm thicker workpiece yog sim ces, ntawm chav kawm, lub clampbar yuav tshem tawm.

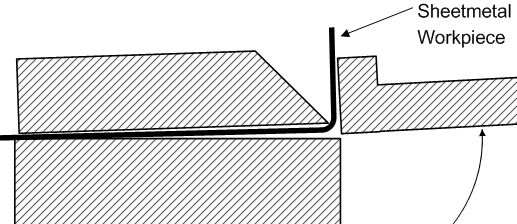

Daim duab no qhia tau hais tias yog lub qhov ntswg ntug ntawm lub clampbar yog radiused me ntsis, es tsis ntse, ces qhov sib txawv ntawm huab cua rau tuab dabtsi yog khoov yuav txo.

Tseeb, qhov no yog qhov teeb meem thiab qhov ua tau zoo Magnabend yuav muaj lub clampbar nrog lub voj voog ncig.(Ib ntug radiused kuj tseem tsawg dua rau kev puas tsuaj los ntawm kev sib tsoo piv nrog cov ntug ntse).

Marginal hom ntawm Khoov Failure:

Yog tias qhov khoov tau sim ntawm lub workpiece tuab heev ces lub tshuab yuav tsis khoov nws vim hais tias lub clampbar yuav tsuas nqa tawm.(Zoo hmoo qhov no tsis tshwm sim hauv txoj kev ua yeeb yam; lub clampbar cia li cia mus ntsiag to).

Txawm li cas los xij, yog tias cov khoom siv khoov tsuas yog me ntsis ntau dua li qhov khoov lub peev xwm ntawm cov hlau nplaum, feem ntau yuav ua li cas yog qhov khoov yuav hais txog 60 degrees thiab tom qab ntawd lub clampbar yuav pib xaub rov qab.Hauv hom kev ua tsis tiav no cov hlau nplaum tsuas tuaj yeem tiv thaiv qhov khoov tsis ncaj los ntawm kev tsim kev sib txhuam ntawm lub workpiece thiab lub txaj ntawm cov hlau nplaum.

Lub thickness sib txawv ntawm qhov tsis ua hauj lwm vim nqa tawm thiab tsis ua hauj lwm vim zawv zawg feem ntau tsis ntau heev.

Kev tshem tawm tsis ua haujlwm yog vim lub workpiece levering pem hauv ntej ntug ntawm lub clampbar upwards.Lub clamping quab yuam nyob rau pem hauv ntej ntug ntawm lub clampbar yog tsuas yog dab tsi resists qhov no.Clamping ntawm ntug ntug tsis tshua muaj txiaj ntsig vim tias nws nyob ze rau qhov chaw clampbar yog pivoted.Qhov tseeb nws tsuas yog ib nrab ntawm tag nrho cov clamping quab yuam uas resists nqa-tawm.

Ntawm qhov tod tes zawv zawg yog tiv thaiv los ntawm tag nrho cov clamping quab yuam tab sis tsuas yog los ntawm kev sib txhuam yog li qhov tseeb tiv thaiv nyob ntawm qhov coefficient ntawm kev sib txhuam ntawm lub workpiece thiab qhov chaw ntawm cov hlau nplaum.

Rau cov hlau huv thiab qhuav, kev sib txhuam coefficient tuaj yeem siab li 0.8, tab sis yog tias lubrication tam sim no ces nws yuav qis li 0.2.Feem ntau nws yuav yog qhov chaw nyob nruab nrab ntawm xws li cov marginal hom ntawm khoov tsis ua hauj lwm feem ntau yog vim zawv zawg, tab sis kev sim ua kom muaj kev sib txhuam ntawm qhov chaw ntawm cov hlau nplaum tau pom tias tsis tsim nyog.

Thickness Muaj peev xwm:

Rau E-hom hlau nplaum lub cev 98mm dav thiab 48mm sib sib zog nqus thiab nrog 3,800 ampere-tig coil, tag nrho ntev dabtsi yog khoov muaj peev xwm yog 1.6mm.Qhov tuab no siv rau ob daim ntawv steel thiab aluminium ntawv.Yuav muaj tsawg clamping ntawm daim ntawv txhuas tab sis nws yuav tsum tau tsawg dua torque los khoov nws yog li qhov no them nyiaj rau hauv txoj hauv kev kom muab lub peev xwm zoo sib xws rau ob hom hlau.

Yuav tsum muaj qee qhov lus ceeb toom ntawm lub peev xwm khoov tau hais tseg: Qhov tseem ceeb yog tias lub zog tawm ntawm cov ntawv hlau tuaj yeem sib txawv.Lub peev xwm 1.6 hli siv rau cov hlau uas muaj kev ntxhov siab txog li 250 MPa thiab rau txhuas nrog kev ntxhov siab txog li 140 MPa.

Lub thickness muaj peev xwm nyob rau hauv stainless hlau yog hais txog 1.0mm.Lub peev xwm no tsawg dua li lwm cov hlau vim tias cov hlau tsis muaj hlau feem ntau tsis yog hlau nplaum thiab tseem muaj qhov ua rau muaj kev ntxhov siab ntau.

Lwm qhov tseem ceeb yog qhov kub ntawm cov hlau nplaum.Yog hais tias cov hlau nplaum tau raug tso cai los ua kub ces qhov kev tiv thaiv ntawm lub kauj yuav siab dua thiab qhov no nyob rau hauv lem yuav ua rau nws kos tsis tshua muaj tam sim no nrog rau qhov txo qis ampere-tig thiab qis clamping quab yuam.(Cov nyhuv no feem ntau yog nruab nrab thiab tsis zoo li yuav ua rau lub tshuab tsis ua raws li nws cov specifications).

Thaum kawg, lub peev xwm thicker Magnabends tuaj yeem ua tau yog tias cov hlau nplaum hla ntu tau ua kom loj dua.

Post lub sij hawm: Aug-12-2022